Process Engineering

Nasato Consulting Ltd. offers a broad spectrum of process engineering capabilities in sulfur recovery, gas treating and sour water processing. Areas of specific expertise include:

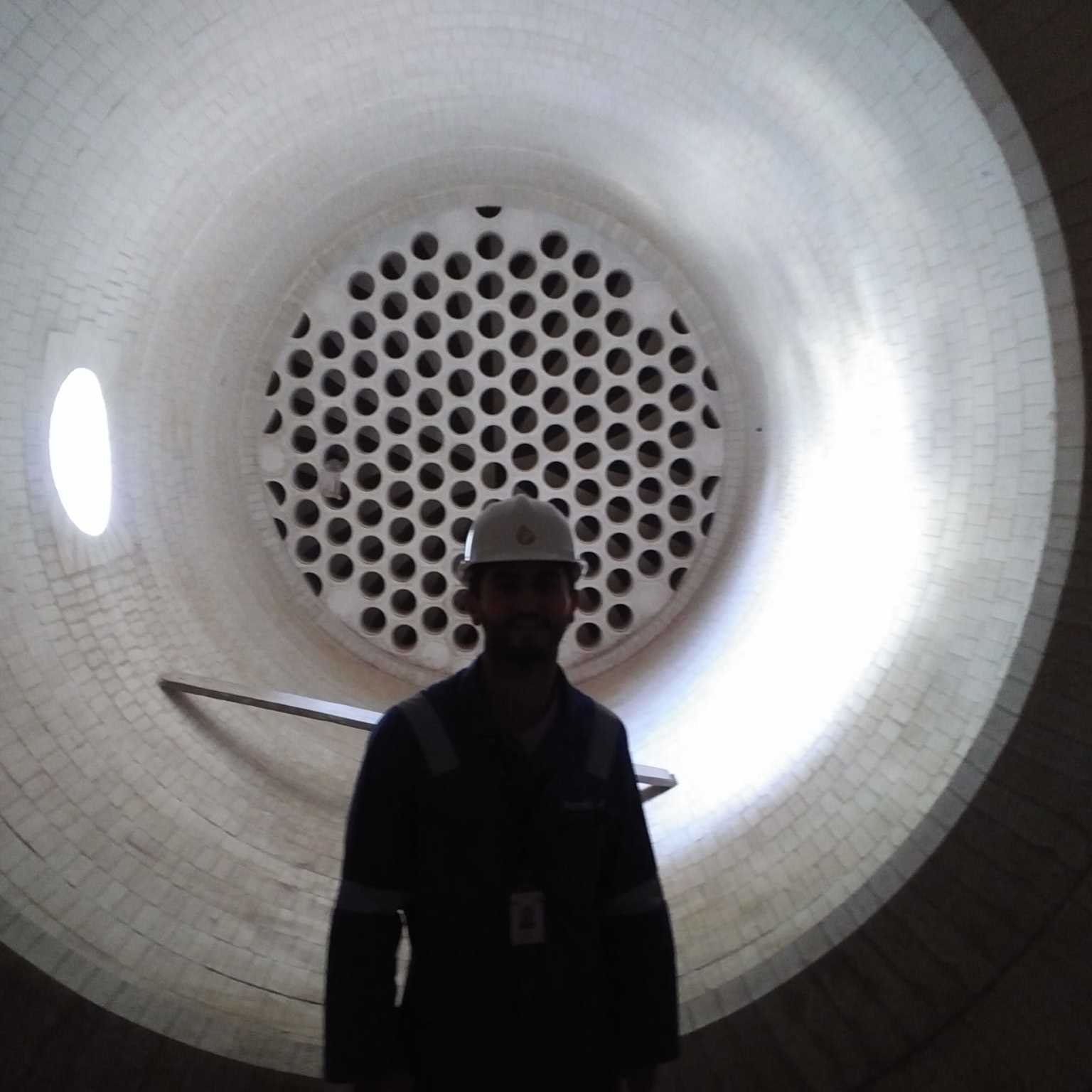

- Claus sulfur recovery, tail gas clean-up, and abatement of SO2 emissions.

- Oxygen enrichment of Claus plants.

- Sulfur degassing.

- Refinery and natural gas treating for acid gas removal.

- Sour water stripping for removal of NH3 and H2S.

- Extensive design and operating experience.

- Extensive design and operating experience with SUPERCLAUS® technologies.

We specialize in basic engineering design, process and project feasibility evaluations, project bid package preparation, operating manual preparation, plant startup and performance testing supervision, plant troubleshooting/reliability studies, and staff training seminars.

Typical projects are comprised of Nasato Consulting Ltd. conducting on-site visits, providing a Process Design Package followed by oversight and assistance as requested during detailed design, procurement, construction, HAZOPS and startup. Nasato Consulting Ltd. has extensive experience with project execution with major EPCs and operating companies worldwide, and has built a reputation for identifying problems and providing cost-effective technology neutral solutions. Our design focus is on safety, efficiency, long-term reliability, and lowest life-time cost of ownership. Each design is tailored to meet the specific needs of our client and the site.

Services

Process Studies

Reliability Studies - Feasibility Studies - Process Evaluations - ACT Studies - Root Cause Analysis

Process Design

Process Design Packages - Startup, Shutdown and Operating Manual Development - Process Hazard Review Participation

Commissioning and Testing

Field Installation Checkout - Operations and Process Staff Training - Startup and Shutdown Assistance - Performance Testing Assistance

Operations

Troubleshooting - Operating Procedure Review - Evaluation Studies